Reactive Dyes: Classification, Dyeing Mechanism, Application & Stripping

Reactive dyes are a significant class of dyes used extensively in the textile industry. They are known for their vibrant colors, excellent color fastness properties, and ability to form a covalent bond with textile fibers. This blog delves into the classification, dyeing mechanism, application processes, and stripping methods for reactive dyes.

Classification of Reactive Dyes

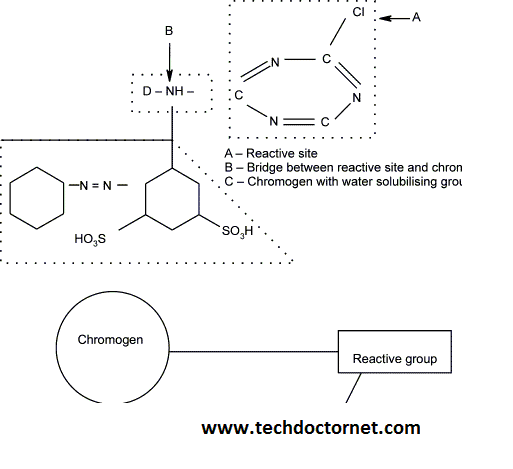

Reactive dyes can be classified based on their reactive groups and application methods. The primary categories include:

- Based on Reactive Groups:

- Monochlorotriazine (MCT): Also known as cold brand dyes, they react with fibers at lower temperatures (30-60°C).

- Dichlorotriazine (DCT): Also known as hot brand dyes, they require higher temperatures (80-90°C) for fixation.

- Vinyl Sulfone: Known for their excellent fastness properties and high reactivity.

- Heterocyclic Halogen-Containing: Include various other halogen-based reactive groups.

- Based on Application Methods:

- Cold Dyes: Applied at low temperatures, suitable for sensitive fabrics.

- Hot Dyes: Applied at high temperatures, ideal for robust fabrics.

- High Exhaust (HE) Dyes: Designed for high exhaustion methods.

- Low Salt (LS) Dyes: Require less salt, making them more environmentally friendly.

Dyeing Mechanism

The dyeing mechanism of reactive dyes involves several key steps:

- Adsorption: The dye molecules are adsorbed onto the surface of the fiber. This is influenced by factors such as temperature, pH, and the presence of electrolytes.

- Diffusion: The dye diffuses into the fiber interior. This depends on the fiber type and the molecular size of the dye.

- Fixation: The reactive groups of the dye form covalent bonds with the hydroxyl groups of cellulose (in cotton) or amino groups (in wool and silk). This bond formation is facilitated by the alkaline conditions (pH 10-11).

Application Process

The application of reactive dyes typically involves the following steps:

- Preparation: The fabric is prepared by scouring and bleaching to remove impurities and enhance dye uptake.

- Dyeing: The fabric is immersed in a dye bath containing the reactive dye, salt (to promote dye uptake), and an alkali (to facilitate fixation). Temperature and pH are carefully controlled.

- Washing Off: Post dyeing, the fabric undergoes thorough washing to remove unfixed dye. This ensures good fastness properties and prevents bleeding.

- Finishing: The fabric is finished with treatments to enhance its appearance and performance characteristics.

Stripping of Reactive Dyes

Stripping is the process of removing dye from a fabric, usually to correct dyeing faults or for re-dyeing. The methods for stripping reactive dyes include:

- Chemical Stripping:

- Reducing Agents: Sodium hydrosulfite or thiourea dioxide are commonly used. They break the covalent bonds between the dye and the fiber.

- Oxidizing Agents: Hydrogen peroxide or sodium hypochlorite can also be used, although they may damage the fiber.

- Alkaline Stripping:

- Using a high pH solution, usually combined with a reducing agent, to break the dye-fiber bond.

- Solvent Stripping:

- Involves the use of organic solvents to dissolve the dye. This method is less common due to environmental and safety concerns.

Takeaway

Reactive dyes play a crucial role in the textile industry, offering vibrant colors and excellent fastness properties. Understanding their classification, dyeing mechanism, application, and stripping processes is essential for achieving optimal dyeing results and maintaining fabric quality. By mastering these aspects, textile professionals can ensure high-quality, durable, and aesthetically pleasing fabrics.