Introduction

Shape Memory Polymer (SMPs) are a class of smart materials that have the remarkable ability to return from a deformed state to their original shape when subjected to an external stimulus, such as heat, light, or an electric field. This unique property has opened up innovative possibilities across various industries, including the textile sector. In this blog, we will explore the applications of Shape Memory Polymer in textiles, highlighting how this technology is revolutionizing fabric performance and design. Lets discuss more about Shape Memory Polymer in textiles.

What are Shape Memory Polymers (SMPs)?

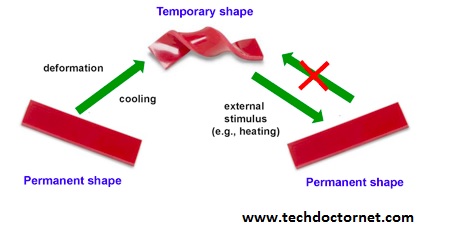

SMPs are polymers that can “remember” their original shape. They can be temporarily deformed and then revert to their predetermined shape upon exposure to a specific stimulus. This characteristic is due to the molecular structure of SMPs, which can be designed to respond to different triggers.

Imagine a material that can be deformed and then miraculously “remember” its original shape when exposed to a specific trigger, like heat or light. That’s the magic of SMPs! These smart materials are engineered to possess two key properties: shape memory and shape recovery. External stimuli like temperature, light, or even moisture can trigger the material to “remember” its original form.

SMPs Revolutionizing Textiles:

The unique properties of SMPs open doors to a world of possibilities in the textile industry. Here’s a glimpse into some of the most exciting applications:

- Wrinkle-Free Fabrics: Say goodbye to ironing! SMP-treated fabrics can recover from wrinkles and creases upon exposure to heat, ensuring crisp, polished garments that stay that way.

- Adaptive Clothing: Imagine clothes that adjust to your body temperature. SMPs can be incorporated into clothing to create garments that offer a comfortable fit regardless of fluctuations in body heat. This could be particularly beneficial for activewear or clothing designed for extreme weather conditions.

- Smart Bandages and Wound Dressings: SMPs can be used to create bandages that conform to the body and provide a better fit for wound healing. They could also be designed to release medication at a controlled rate when triggered by changes in body temperature.

- Functional Textiles: SMPs can be used to create interactive textiles that respond to the environment. Imagine curtains that automatically adjust to regulate sunlight or sportswear that enhances breathability during exercise.

- Fashion with a Twist: SMPs open doors for innovative fashion design. Imagine garments that change shape or form based on temperature, creating dynamic and interactive clothing experiences.

Key Properties of SMPs in Textiles

- Shape Memory Effect: The primary feature of SMPs is their ability to change shape and return to their original form. This property can be harnessed in textiles to create garments that adapt to different conditions or functions.

- Stimuli-Responsiveness: SMPs can be engineered to respond to various stimuli, including temperature, light, moisture, and electric fields. This responsiveness can be integrated into textiles for a range of applications.

- Versatility: SMPs can be combined with other materials, such as natural or synthetic fibers, to enhance their properties and expand their applications in textiles.

Applications of SMPs in Textiles

1. Adaptive Clothing

One of the most exciting applications of SMPs in textiles is the creation of adaptive clothing. Garments made with SMP-infused fabrics can change their properties based on environmental conditions or user needs. For example:

- Temperature-Regulating Clothing: SMPs can be used to create fabrics that expand or contract in response to temperature changes. This can help regulate the wearer’s body temperature, providing warmth in cold conditions and breathability in hot conditions.

- Shape-Shifting Fashion: Designers can create clothing that changes shape or fit when exposed to specific triggers, allowing for customizable fashion that adapts to the wearer’s preferences or activities.

2. Medical Textiles

SMPs have significant potential in the field of medical textiles, where they can improve the functionality and comfort of medical garments and devices:

- Compression Garments: SMP-infused textiles can be used to create compression garments that adjust their tightness based on the wearer’s needs, improving blood circulation and reducing swelling.

- Smart Bandages: Bandages made with SMPs can change their shape to apply optimal pressure or adapt to the contours of a wound, enhancing healing and patient comfort.

3. Smart Textiles for Sports and Activewear

In the realm of sports and activewear, SMPs can enhance performance and comfort:

- Form-Fitting Activewear: SMPs can be used to create sportswear that adjusts its fit based on the wearer’s movements or body temperature, providing optimal support and comfort.

- Protective Gear: SMPs can be integrated into protective sports gear to create items that change shape or rigidity upon impact, offering better protection for athletes.

4. Textiles for Home and Interior Design

SMPs can also be applied in home textiles and interior design, offering functional and aesthetic benefits:

- Smart Curtains and Blinds: Curtains and blinds made with SMPs can change their shape or opacity in response to light or temperature, providing better energy efficiency and privacy.

- Adaptive Upholstery: Furniture upholstery can be designed to adjust its firmness or shape based on the user’s preferences, enhancing comfort and ergonomics.

5. Responsive Technical Textiles

In technical textiles, SMPs can be used to create fabrics that respond to environmental changes, improving functionality in various applications:

- Military and Tactical Gear: SMPs can be used in military clothing and gear to provide adaptive camouflage or temperature regulation, enhancing the effectiveness and comfort of soldiers.

- Industrial Applications: SMP-infused textiles can be used in industrial settings for applications such as smart filters that change their porosity based on conditions, optimizing performance and efficiency.

The Future of SMP Textiles:

The application of SMPs in textiles is still in its early stages, but the potential is vast. As research and development progress, we can expect to see even more innovative and functional fabrics emerge. SMPs could revolutionize everything from everyday clothing to medical textiles, creating a future where comfort, functionality, and style go hand-in-hand.

Challenges and Future Directions

While the potential applications of SMPs in textiles are vast, there are challenges to be addressed:

- Durability and Longevity: Ensuring that SMP-infused textiles maintain their functionality over time and through repeated use and washing is a critical challenge.

- Cost and Scalability: Developing cost-effective manufacturing processes for SMP-infused textiles is essential for widespread adoption in the market.

Despite these challenges, ongoing research and technological advancements are paving the way for broader applications and improved performance of SMPs in textiles.

Takeaway

Shape Memory Polymer (SMPs) represent a transformative innovation in the textile industry, offering new possibilities for adaptive, responsive, and functional fabrics. From adaptive clothing and medical textiles to smart sportswear and home decor, SMPs are poised to revolutionize how we design, manufacture, and use textiles. As research continues and technology advances, we can expect to see even more exciting applications of SMPs in the textile sector, enhancing both functionality and aesthetics in everyday fabrics.