Understanding Positive & Negative Tappet Shedding Mechanisms

In the textile weaving industry, shedding mechanisms play a crucial role in fabric production. The tappet shedding mechanism is one of the oldest and most widely used systems. This blog explores the intricacies of tappet shedding, its positive and negative types, scope, and advantages.

What is Tappet Shedding Mechanism?

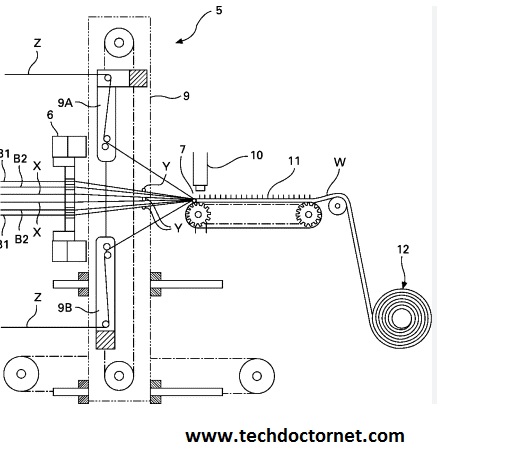

Tappet shedding is a mechanical method used in weaving looms to raise and lower the warp yarns to form a shed. This shed allows the weft yarn to pass through, creating the woven fabric. The mechanism consists of tappets (cams) mounted on a shaft that control the movement of heald frames, which in turn manipulate the warp threads.

Types Of Shedding

There are mainly three types of shedding namely.

- Tappet Shedding.

- Dobby Shedding.

- Jacquard Shedding.

1. Positive Tappet Shedding

In a positive tappet shedding mechanism, the tappets control both the lifting and the lowering of the heald frames. This ensures precise and synchronized movements, which is particularly beneficial for high-speed weaving and complex fabric patterns.

2. Dobby Shedding.

Dobby shedding is an advanced mechanical system used in weaving looms to raise and lower warp yarns in a predetermined sequence. This mechanism allows for the creation of intricate patterns by controlling the movement of multiple heald frames. The term “dobby” is derived from “draw boy,” referring to the early days of weaving when a draw boy manually controlled the warp threads.

How Dobby Shedding Works

The dobby shedding mechanism operates through a series of controlled movements:

Pattern Control: The pattern to be woven is pre-determined and programmed into the dobby mechanism. This can be done using punched cards, electronic systems, or computer-aided design software.

Lever Action: The dobby system uses levers and hooks to control the movement of heald frames. Each hook corresponds to a specific warp thread.

Shed Formation: As the loom operates, the dobby mechanism raises and lowers the heald frames in the correct sequence, forming the shed through which the weft yarn passes.

Synchronization: The movement of the dobby mechanism is synchronized with the loom’s other components to ensure smooth and efficient weaving.

Types of Dobby Shedding

Dobby shedding mechanisms can be classified into two main types: mechanical dobby and electronic dobby.

-Mechanical Dobby

Mechanical dobby shedding uses punched cards or rotary dobby systems to control the pattern. The cards or rotary wheels have holes or slots corresponding to the design, and the levers and hooks engage accordingly to form the pattern.

3. Jacquard Shedding.

Jacquard shedding is an advanced shedding mechanism used in weaving looms to control individual warp threads, allowing for the creation of highly complex patterns. Named after its inventor, Joseph Marie Jacquard, this mechanism eliminates the limitations of traditional shedding systems by providing precise control over each warp thread, enabling the production of intricate and elaborate designs.

How Jacquard Shedding Works

The Jacquard shedding mechanism operates through a series of coordinated steps:

Pattern Input: The desired pattern is input into the Jacquard machine. Originally, this was done using punched cards, but modern systems use computer-aided design (CAD) software for digital pattern input.

Selection: Each warp thread is controlled by a hook attached to a harness cord. The pattern input system determines which hooks are lifted or lowered.

Shed Formation: As the loom operates, the selected hooks raise specific warp threads, forming the shed through which the weft yarn is passed.

Synchronization: The Jacquard mechanism works in sync with the loom’s other components to ensure smooth and accurate weaving.

Types of Jacquard Shedding

Jacquard shedding mechanisms can be classified into mechanical and electronic types.

Mechanical Jacquard

Mechanical Jacquard systems use punched cards to control the lifting of warp threads. Each hole in the card corresponds to a specific hook, and the sequence of cards determines the pattern.

The Scope of Tappet Shedding: Weaving’s Simple Champion

Tappet shedding excels in weaving scenarios with a limited number of heald shafts (typically up to 8). It’s ideal for producing basic weaves like plain weave, twill, and simple satin or sateen. However, for more complex weaves requiring intricate heald shaft movements, dobby or Jacquard shedding mechanisms offer greater versatility.

Positive and Negative Tappet Shedding

Tappet shedding mechanisms can be categorized into two types: positive and negative.

Positive Tappet Shedding

In a positive tappet shedding mechanism, the tappets directly control both the lifting and lowering of the heald frames. This type ensures precise and controlled movement, which is particularly advantageous for high-speed weaving and complex patterns.

Advantages of Positive Tappet Shedding:

- Precision Control: Provides accurate control over heald frame movement.

- High-Speed Weaving: Suitable for high-speed operations without compromising on quality.

- Complex Patterns: Ideal for creating intricate fabric patterns.

- Reduced Wear and Tear: Less strain on heald frames and warp threads.

Negative Tappet Shedding

In a negative tappet shedding mechanism, the tappets control only the lifting of the heald frames, and the lowering is achieved by gravity or springs. This type is simpler and less expensive but may not be suitable for high-speed weaving.

Advantages of Negative Tappet Shedding:

- Cost-Effective: Lower initial investment and maintenance costs.

- Simplicity: Easier to operate and maintain due to fewer moving parts.

- Suitable for Simple Fabrics: Ideal for weaving plain or simple fabrics.

Scope of Tappet Shedding Mechanisms

Tappet shedding mechanisms are versatile and can be used in various textile applications. Their scope includes:

- Plain Weaving: Suitable for producing basic fabric structures like plain weave.

- Pattern Weaving: Capable of creating simple patterns with the right tappet design.

- Technical Textiles: Applicable in weaving fabrics for industrial and technical uses.

- Home Textiles: Used in manufacturing household fabrics such as curtains, bed linens, and upholstery.

Advantages of Tappet Shedding Mechanisms

- Versatility: Can handle a wide range of fabric types and patterns.

- Durability: Robust construction ensures long-term use with minimal breakdowns.

- Efficiency: High operational efficiency with consistent fabric quality.

- Ease of Use: Simple design makes it user-friendly for operators.

- Customization: Tappet shapes can be customized to produce specific fabric designs.

Takeaway

Tappet shedding mechanisms remain a cornerstone in the textile weaving industry due to their reliability, versatility, and efficiency. Whether opting for positive or negative tappet shedding, manufacturers can achieve high-quality fabric production tailored to their specific needs. Understanding the nuances of each type helps in making informed decisions, ensuring optimal performance and fabric quality.